This resulted in our use of a Closet Auger that was more durable than the economical one bought/used by the property owner. We always give the customer top notch approval for trying to attempt to clear an obstruction themselves whenever possible. The reward is solving the problem without the expense of a plumber.

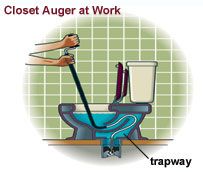

Using the Closet Auger in its design is made to be a handheld, hand crank type drain cable that has a slight hook end with protective covering to protect the trapway of the toilet from porcelain scratching/damage. The goal is to push and turn the closet auger's hand crank as you're using the device, allowing the device to remove/retract the foreign object or obstruction inside the toilet's trapway.

Not always will you retrieve what is blocking the toilet. In cases where soft stoppages exist, it might be excessive toilet paper that is to blame. Others can be the situation of hard or large stools that did not break up through the passage of the trapway. Recent usage of medications or the changing of one's medicine intake can cause an interruption of one's bowel movements resulting in issues such as these that can lead to stoppages or clogged toilets.

The use of the Closet Auger proved successful and the repeated flushing of the toilet to ensure that the trapway was clear offered the guarantee that the stoppage was removed. It is imperative that once a toilet is free from obstruction that multiple flushings take place in order to remove or send the foreign object or matter down the drain line if the Closet Auger does not grab on or retrieve the item causing the blockage.

However, (EXCLUSION TO THE ABOVE PARAGRAPH)

If you are aware that an object or item is something that might end up causing a clog in the drain piping due to its size or shape, then it's important that the toilet is removed from the closet flange mounted to the floor and attempt to remove the obstruction by retrieval. This will provide the guarantee that the item will not cause future backups in the piping system.